Ukraine, War, Tubes, and the Sanctions on Russia

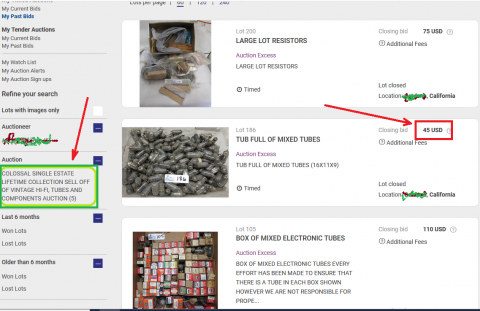

Posted by Zander on Wednesday, 30 March 2022The vacuum tube market has gone into a tailspin with Russia's attack on, and invasion of, Ukraine, and the subsequent world response holding Russia in contempt for doing so.

Mike Matthews, owner of ElectroHarmonix and reseller of Russian tubes has indicated that, yes, with the attack on Ukraine, and world sanctions against Russia, that for the foreseeable future, Russian tubes are no more.